R.T. Custer, co-founder and CEO of Vortic Watches.

Perfect timing

Alumnus uses 3D printing technology as the basis for new watch company

9/6/2016

UNIVERSITY PARK, Pa. — R.T. Custer (IE ’14) started out at Penn State like any other undergraduate engineering student, taking the basic engineering courses his first two years and learning about all of his options. He ended up choosing to pursue his bachelor’s degree in industrial engineering (IE).

“I went with IE because I wanted a good mix of business and engineering,” said Custer. “The supply chain courses satisfied my business and logistics side, and the manufacturing courses satisfied my passion for true engineering.”

A native of Reading, Pennsylvania, Custer would return home over breaks and during the summers to help run his family’s Christmas tree farm and he eventually started a painting company with his friend and fellow Penn Stater Tyler Wolfe (MATH ’14).

On the golf course one day, Custer and Wolfe started discussing how it was difficult to wear any watch while playing sports — such as golf — because they never quite stay where they should on the arm — they were always too loose or too tight.

“We had an idea for an adjustable wristband that could fit any watch and be easily adjusted with the turn of a knob,” said Custer. “Then we started tossing around the idea of starting an engineering design and manufacturing company that would make unique watches and we focused on how to take advantage of the opportunities available to us as students at Penn State.”

During their last two years at Penn State, Custer and Wolfe — along with friends Frank Barber (IE ’13) and Mac Frederick (AD/PR ’13) — built the foundation for Vortic Watch Company by writing business plans in their entrepreneurship courses, prototyping their products on the University’s 3D printers, and later sponsoring capstone design projects through the Learning Factory.

Before leaving Penn State, the friends turned business partners secured one patent, with several in the making, so they felt they had some good momentum on which to build.

After graduating in May 2014, Custer moved to Fort Collins, Colorado, to begin working as a logistics engineer in Walmart’s Engineering Service Division. While he was busy renovating distribution centers to make them more efficient during the day, Custer was pouring the rest of his time into building the watch company.

Custer, who minored in engineering leadership development and engineering entrepreneurship, and his partners worked tirelessly to launch their first series, The American Artisan Series, on Kickstarter in 2014.

“The products in the series are the only wristwatches that are 100 percent made in the United States and they are built using antique pocket watches made by some of the great American watch companies, such as Hamilton, Waltham, and Elgin,” said Custer.

The company saw tremendous interest after the launch through its website, built by Vortic’s lead designer, Andy Bickford (GD ’13), along with its social media outlets, and before Custer and his colleagues knew it, they were receiving national attention.

Vortic Watch Company was featured by The New York Times, The Boston Globe, NPR, WatchTime magazine, Revolution magazine, Fortune – Asia, and other publications, which touted not only the company’s excellent design work but how Custer and his partners built the business from the ground up.

The company has grown so much that Custer resigned from his position at Walmart in May 2016 to put all of his efforts into Vortic, which is based out of Fort Collins.

“I knew that if I put 100 percent of my time into Vortic, I could grow the business faster,” said Custer. “I’d rather make half as much money and love what I do than make a big salary and not be as happy. Walmart is a great company and took care of me financially and gave me some really awesome projects, but running a company gives me so much more personal satisfaction.”

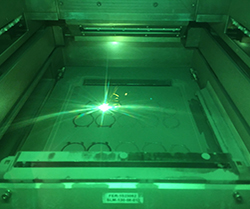

The company is preparing to launch its Journeyman Series and was recently awarded a $40,000 grant through America Makes and the Penn State Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D). The grant will go toward studying 3D-printed metals and exploring how to make the process more achievable for consumer products.

“Right now, 3D-printed titanium is used almost exclusively to prototype high precision parts for the aerospace and industrial industries,” said Custer. “But we will be 3D printing titanium for our new watch cases this fall which will result in a lightweight, strong, customizable case…the first of its kind.”

Custer returns to campus frequently to talk to budding entrepreneurs and recently took part in the College of Information Sciences and Technology’s Startup Week.

Through all of the setbacks and all of his successes, Custer traces his success and growing company back to his friendships and his background in IE at Penn State.

“I learned all about Solidworks and how to design and prototype my ideas as a student at Penn State, and I still use it today,” said Custer. “I learned about 3D printing and built my first prototype in Professor Sanjay Joshi’s Additive Manufacturing Process and Reverse Engineering course. I learned how to optimize our business through the supply chain courses I took and I learned how to work with suppliers and design products that have correct tolerances through the manufacturing courses.

“I owe a tremendous amount of my success to the IE program at Penn State and the university as a whole, and I’m so proud to be running this company alongside a group of fellow Penn Staters.”