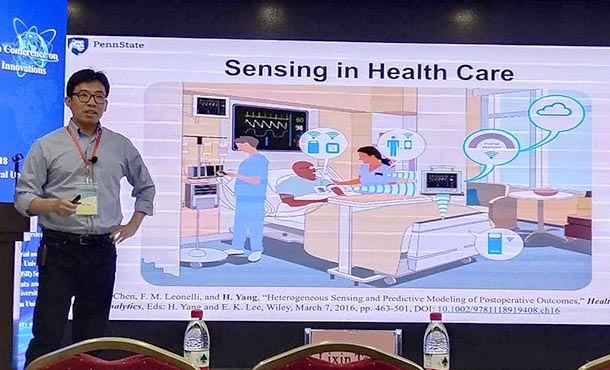

Hui Yang presents his research on sensor-based modeling at the 3rd Sino-US Research Conference On Quality, Analytics and Control. IMAGE: HUI YANG

Digitizing health care services

3/15/2019

UNIVERSITY PARK, Pa. — As the world continues its rapid transformation into the digital age, thinkers who can convert big data into knowledge are essential to maneuvering strategically in many sectors. This is particularly true when looking at complex systems, where a non-linear structure makes prediction and modeling of the systems difficult.

Hui Yang is an associate professor in the Penn State Harold and Inge Marcus Department of Industrial and Manufacturing Engineering. Through his expertise in complex system monitoring, modeling and control, Yang and his students discover new ways to optimize the design of various service industries through data-driven innovation.

Yang is a proponent of Smart Manufacturing through the Internet of Things (IoT). The IoT is a new technology that unites all components of a service, manufacturing or any other complex system, through the internet. This interconnectedness means that a system experiences almost limitless communication of data, which also means increased efficiency across the system.

One of his research projects, Better Heart Beats Through Engineering, seeks to improve the modeling of cardiac function through physics-based modeling and sensor-based informatics. Yang believes that physiologists and cardiologists can use this improved modeling system to better understand cardiac functions in health and disease. Simulation modeling of cardiac functions allows medical professionals to optimize medical decision making.

Yang continued his contribution to the service sector when he edited the book, “Advances in Service Science: Proceedings of the 2018 INFORMS International Conference on Service Science.” The book contains cutting-edge research and development of service systems from top researchers in the field. Similarly, it highlights new technology across the fields of health care, logistics, transportation and public services.

At Penn State, Service Enterprise Engineering (SEE) 360 works to educate students of the demand for engineers in the service sectors. Engineers are praised for their ability to optimize service systems to work more efficiently. A SEE minor is available to students who wish to learn about the potential for data-driven innovation in service industries.

As a SEE 360 supported faculty member, Yang teaches various classes on modeling, monitoring and controlling complex systems in the service industry. Yang emphasizes that this continuity, from modeling to control, is imperative to understanding such systems.

“Basically, it goes from design of experiments to engineering analytics, statistical modeling, to stochastic processes and also to the process optimization and control,” he said.

With regard to system modeling, Yang teaches his students to design experiments with a statistical approach for optimal design.

“Optimal design of an experiment means you minimize the cost to run the experiments or minimize the human investment, human effort, to run the experiments, and any machinery costs to run the experiments,” he explained. “But you want to maximize the effectiveness of the experiments, to gain the knowledge from the experiments.”

Gaining knowledge from experiments is the end goal of all researchers. As experiments bring more and more data for researching complex systems, Yang also offers courses in data analytics.

“Statistics is more advanced than just to derive some statistics from data like a mean and average. Now you have to develop data-driven models to model the data and then use the model to guide the prediction, make the inference, and then guide the optimization of the system,” Yang said.

In addition, Yang teaches students to use informatics to better control systems. Researchers use informatics to pull useful information from a system to understand a system in a more robust manner. By fully understanding a system, researchers can account for any unpredictability, or stochasticity, in a system.

Many of Yang’s previous students have gone on to careers in teaching at other universities, a trend that he appreciates. Yang believes this is because industry and academics alike are realizing the advantages to be had from researching complex systems and big data.

“My Ph.D. students have become assistant professors after graduation from Penn State. They are now at Texas Tech, University of Texas Arlington, Oklahoma State, they are assistant professors. They are teaching this type of service and data related class,” he said. “So, the impact is not just here at Penn State, we’re graduating a lot of students from undergraduate class and from graduate class, and the impact of service science education also extend to other universities, too.”

If you would like to learn more about Hui Yang, you can visit his website. For more information, or to learn how to get involved with SEE 360, contact Bárbara Venegas at 814-863-5742 or bbv105@psu.edu.

For more updates from Service Enterprise Initiative 360, visit our website.